Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

Comparison of different comminution flowsheets in terms of

2018年8月15日 Comparative mineral liberation and separation tests of hematite ores were conducted for three comminution flowsheet options to produce relatively fine

Pre-Concentration of Ultrafine Crushed Hematite Ores: Separation ...

2014年6月3日 In this study, a lean hematite ore was crushed to produce ultrafine particles using a high pressure grinding roll and then pre-concentrated using a high gradient

Influence of process parameters of dry high intensity magnetic ...

2017年3月10日 To predict the separation of the hematite from this low-grade ore, the images were analyzed, and the theoretical yield-grade curve (for the low grade iron ore

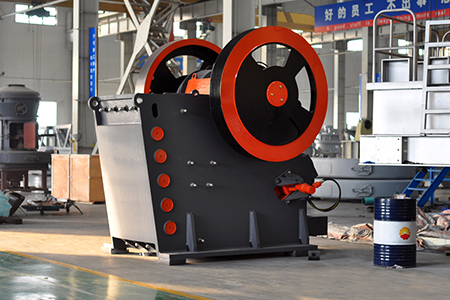

Hematite Separation Process - JXSC Machinery

The hematite separation process mainly involves various methods to extract valuable minerals from the ore, including crushing, grinding, magnetic separation and flotation.

The hematite ore liberation and separation properties in

2021年2月22日 In order to improve grinding efficiency and weaken over-grinding in the whole grinding process, the new process of “ultra-crushing in HPGR – classified separation” was proposed with an Anshan style

The hematite ore liberation and separation properties in different ...

DOI: 10.1080/01496395.2021.1878375. Authors: Lei Liu. Abstract. In order to improve grinding efficiency and weaken over-grinding in the whole grinding process, the new

Beneficiation of Low-Grade Hematite Iron Ore Fines by

Hematite ore’s magnetic characteristics were significantly impacted by magnetizing roasting. By selectively magnetizing roasting, hematite is transformed into magnetite. With an Fe